Shipping produce is no easy feat, and cranberry transportation is no different. Any time you’re dealing with a perishable commodity, time is of the essence to get it delivered to stores across the U.S. before it begins to spoil. In addition to that, delicate fruits like berries need to be handled carefully, otherwise they could end up getting smashed before they make it to their destination! With so much to worry about, it can be stressful to try to find the right shipping partner on top of it all—but don’t worry! This guide will walk you through the process of transporting cranberries all across the U.S., from harvest to delivery.

As with all perishable commodities, cranberry transportation should be executed carefully. Temperatures should be kept cool and consistent to preserve quality, and the cranberries should be packaged in a way that doesn’t put too much pressure on individual berries. Alternatives to shipping cranberries fresh include cranberry juice, frozen cranberries, and canned cranberry sauce.

Cranberries are actually one of the few types of berries that are native to the U.S. They are grown in northern U.S. states, such as New Jersey, Massachusetts, Oregon, Washington, and Wisconsin. Wisconsin and Massachusetts provide the vast majority of cranberries in the United States, collectively producing more than 90% of all the cranberries grown in the nation.

Need help with freight shipping from New Jersey to California? See how a strategic freight partner can help.

The average person in the U.S. consumes 2.3 pounds of cranberries a year. That’s a total national consumption of more than 750 million pounds of cranberries! As you can imagine, the logistics required to move all those berries from the northern states across the entire U.S. are complex and challenging.

However, in order to make sure your cranberries will survive being transported, you actually need to first turn your attention to how the berries are being harvested. Improper technique can deteriorate the quality of the berries and lead to problems after they are packed and loaded onto a truck.

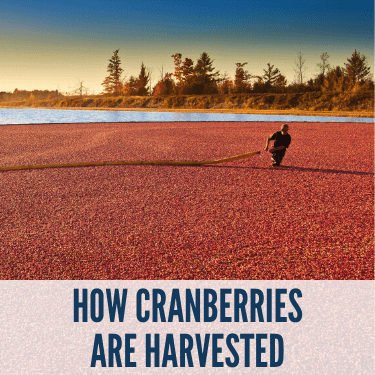

The cranberry harvest begins in mid-September for most cranberry producing states, and runs through mid-November. There are two main ways that cranberries are harvested: dry harvest, and wet harvest.

Dry harvesting is a popular choice for harvesting for smaller farms, and it is much more convenient than wet harvesting. Dry harvesting doesn’t require as much coordination or special machinery—it simply requires a mechanical harvester to pull the berries off the vines. It resembles a lawnmower, and as it is pushed over the top of the vines, rotating spokes pull the berries onto a conveyor belt that dumps them into a holding bin at the back of the machine. Farmers can then empty those bins into larger buckets or bins by hand. However, because of the nature of the machine, it may end up damaging some of the cranberries as they are pulled off the vines.

Wet harvesting is a method of harvesting that is so iconic that it has become somewhat of a symbol of the cranberry industry. Scenes of vast bogs filled with floating red berries and autumn trees in the background line the grocery store shelves on bottles of cranberry juice—and with good reason. Wet harvesting is the method most commonly used by large-scale farms that work with major juice companies like Ocean Spray.

Harvesting huge fields of cranberries with mechanical harvesters would take forever, so instead, the bogs are closed off and flooded with roughly 18 inches of water. Then, water reels are sent off on the water to stir up the plants and knock the berries free. Because of little pockets of air inside the cranberries, they float up to the surface of the water. Nets and floating barricades are then used to bring the berries in where they can be collected.

Although cranberries have a tougher skin than most other berries, they should still be handled with care. Bruising or breaking the skin on the berries could speed up spoilage, and it could potentially provide an opportunity for bacteria to infiltrate the entire batch.

To package fresh cranberries safely, you have a few different options. They could be packaged in plastic bags with holes to vent out excess moisture, or you could opt for clamshell packaging or something similar. Then, the packages should be placed in larger, sturdier boxes that will be able to support the weight of palletization.

Alternatively, if you are shipping in bulk, then you can load the cranberries up in plastic or fiberboard bulk bins, and then have those loaded up onto a freight truck for transportation. If the bins are able to close or stack, then that’s even better. However, under no circumstances should the cranberries be stacked directly on, or they will get smashed. Only stack containers that are designed to withstand the weight of being stacked on without putting pressure on the contents inside the containers.

Cranberries do not typically require any temperature regulation if they are being transported short distances. Most cranberries are processed before being sold to consumers, so most fresh berries are transported only a short distance to a processing plant. However, that is going to depend heavily on the weather. If the berries are transported on an unusually warm or cold day, then they might not stay fresh on the way to the facility. In that case, then the truck shipping the berries should be insulated as best as possible, and covered with a heat-reflective tarp if it is open at the top.

If the cranberries you are shipping will be transported fresh for a much longer distance, such as to grocery stores around the U.S., then you will need to utilize different techniques. Cranberries should be kept at a temperature between 2 - 4 degrees Celsius (36 - 39 degrees Fahrenheit) if they will be on the road for more than a few hours. At that temperature, cranberries can be safely stored for up to 4 months, as long as other conditions are favorable. If the cranberries are allowed to get too warm, then they will deteriorate and begin to rot after only a few hours.

On the flip side, however, cranberries are also chilling-sensitive, so they should never be allowed to drop below 0 degrees Celsius (32 degrees Fahrenheit). If the cranberries get too cold, then they will begin to turn brown and the inside of the berry will become tough and rubbery.

Since cranberries are often grown in the north and shipped to southern states, the different climates that the trucks would have to move through could cause temperatures to fluctuate greatly during the trip. This problem is exacerbated by changes in elevation, weather patterns, and delays. In order to ensure that your shipment stays fresh, you should utilize a refrigerated truck. Refrigerated trucks can maintain a very specific temperature for the duration of the trip, regardless of what the conditions are like outside.

Cranberries are often shipped fresh, but they are typically transported to processing plants to be made into various different cranberry products. Cranberry products make up desserts, sides, snacks, beverages, and more, and they are a vital part of Thanksgiving traditions. The holiday just wouldn’t be the same if the turkey couldn’t be accompanied by a can of traditional cranberry sauce.

Cranberries are processed in many different ways to both increase their shelf life and to create a variety of consumer favorite foods. For example, cranberries can be:

Any facility that is used to process cranberries must comply with the Food and Drug Administration (FDA) regulations for food facilities. This includes registering the facility with the FDA, issuing a Hazard Analysis and Critical Control Points (HACCP) plan, and keeping an updated Current Good Manufacturing Practices (CGMP) file to ensure quality, care, and safety in food handling.

In addition to that, the FDA also enforces regulations for the safe and sanitary transport of food, for both fresh produce and processed foods. If the berries will be transported on a freight truck, then that truck would be subject to strict sanitization requirements—even if the berries are canned!

As with other products meant for consumption, juice is subject to FDA regulations. However, there is a separate document issuing the best practices for keeping your juice compliant. This unique guidance is not enforceable, as other methods can be used to achieve the same level of compliance, but it is still handy to reference.

Aside from the regulations, getting juice ready for shipping can be a challenge. The first thing you will need to decide is how to package the juice for shipping. Will it be in bulk containers, or consumer bottles? If it’s packed in bulk, will you be using metal drums, plastic jugs, or something else? If it’s packaged in bottles for grocery stores already, how will you be palletizing the bottles to protect them during shipping? These are all things that you will need to consider.

Transporting juice in bulk to a bottling facility is a relatively easy task. Once you select your containers—likely metal drums or large plastic jugs—you will need to take the proper steps to sanitize them. Make sure that any cleaners you use are FDA approved for use on food containers, too. The last thing you want is to inadvertently contaminate your juice by using the wrong cleaning agent.

Bulk containers are typically easy to stack, and they will fit into the back of a freight truck with little difficulty. However, you may want to consider temperature-controlled options, such as refrigerated shipping, to ensure that your shipment stays fresh for the journey.

Shipping retail bottles of juice is a little more difficult, and you have to be a lot more cautious when it comes to handling the product. Not only are these bottles more fragile than bulk containers, but they are also more likely to burst or crumple as a result of high temperatures or mishandling. Too much heat could build up enough pressure in the bottles to break the seal and cause the juice to leak all over the inside of the truck.

Additionally, palletizing bottles can be difficult too. The bottles should be placed inside larger boxes that will be able to support the weight of palletization. A pallet of unboxed bottles may be able to hold up, but the moment another pallet is stacked on top of it, the weight would crush the bottles on the bottom of the stack.

Cranberries aren't the only thing on the Thanksgiving table that requires freight shipping for transport. Learn more about the turkey supply chain.

You might think that shipping dried cranberries is the easiest thing in the world, but you might be getting ahead of yourself there. Dried cranberries, also known as “craisins,” are still subject to FDA regulations, and although they are more shelf-stable than other types of processed cranberries, improper conditions can still ruin them.

The biggest thing you need to pay attention to when it comes to shipping dried cranberries is temperature. Assuming your craisins are packaged in retail packages, excess heat could result in a buildup of condensation on the inside of the bag. That moisture could cause the dried berries to begin to rot, and could encourage the growth of mold.

Another consequence of letting dried cranberries get too warm is the formation of syrup and the candying of the berry. If left alone in this state, the syrup will ferment, effectively destroying the entire batch. They may also harden, change color, or clump together as a result of excess heat.

If you will be shipping during particularly hot months, especially in southern states, then you should use refrigerated shipping to ensure that your product doesn’t spoil.

Frozen cranberries are a popular choice for bakers, since they are perfect for including in muffins, cookies, pastries, pies, and a variety of other dishes.

Thankfully, frozen cranberries are easy to ship. As long as you have a reliable shipping partner, all you need to do is package and palletize the berries, then establish the optimal temperature, and the partner will do the rest. The berries will be loaded up onto a reefer van or refrigerated freight truck, which is capable of maintaining an exact temperature as long as the truck is not opened before reaching its destination. Because of that, it is best to ship frozen foods as a full truckload instead of LTL, so you can ensure your shipment stays cold for the entire trip.

Cranberry sauce is an important holiday food, and although it can be enjoyed year-round, it is typically treated as a seasonal commodity because of the spikes in demand around Thanksgiving and Christmas.

Canned goods are notorious for being shelf-stable and relatively unaffected by fluctuations in temperature and other conditions. Because of this, they are easy to ship. The most important thing that you will need to understand is the process of palletization. Cans are sturdy, and they generally bear the weight of being stacked on quite well, but there are a few things you’ll still need to consider.

When it comes to palletizing cans, you have two main options to choose from.

If you’ve done everything right, your pallets should be sturdy enough to stack other pallets on top of. This will allow for more space on freight trucks, in warehouses, and temporary storage facilities, which can cut costs for you.

If you’re interested in cranberry transportation, whether fresh, frozen, canned, or otherwise, R+L Global Logistics can help. If you want to learn more, our agents are more than willing to walk you through the process. We can also offer truckload shipping services such as expedited freight options for when you need to get your shipment delivered in a hurry. With our 99.5% on-time delivery record and history of successful deliveries and happy customers, you’ll never want to ship cranberries, sugar beets and other food freight with anyone else!

To learn more about our services, give us a call at (866) 353-7178. You can even request a free quote if you’re ready to ship your goods now.

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470