Rubber is essential for thousands of industrial and domestic products. It goes into everything from tires to bandaids, and manufacturers rely on the constant supply of natural rubber to continue producing those necessities. When so many vital products rely on the commodity, it begs the question: just how is rubber shipped all across the U.S.?

Rubber is shipped in bulk on freight trucks. It has to be packaged very carefully because it is easily contaminated—exposure to the elements can ruin a shipment of rubber quickly. In addition to that, rubber is flammable, so certain safety regulations must be followed.

The most common way for rubber to be shipped is with the use of freight trucks. Rubber is generally considered too heavy, odorous, and expensive to ship by air, so shipping by road is the more convenient option.

However, shipping rubber isn’t as simple as just throwing the raw material onto a truck and sending it on its way. Rubber emits a strong odor, so it cannot be shipped alongside any food or animal products, or anything that the stench could cling to. Additionally, there are many things that could go wrong if the rubber isn’t packaged and handled carefully.

With that said, there is no one-size-fits-all solution for shipping rubber. There are several different ways to package rubber for shipping, depending on what state it’s in.

The way rubber should be packaged for shipping will depend on how much it has been processed, how it has been processed, and what shape it is in. One thing that stays consistent, however, is that metal pallets must be used instead of wood, to prevent splinters from contaminating the rubber.

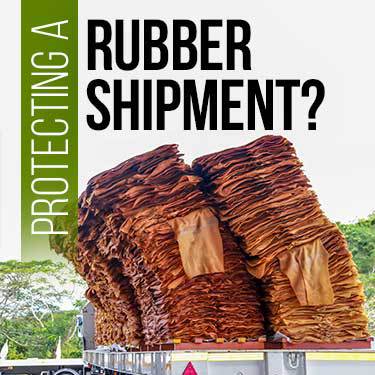

There are many things to consider when shipping rubber. Rubber is a natural commodity, and it is susceptible to rot and decay if it isn’t handled properly.

Rubber shipments should not be handled in rain or snow, because moisture can cause the material to rot, deteriorate, or become discolored. It could also encourage mold to grow, which would render the rubber unusable. If it absolutely must be delivered in bad weather, extra care should be taken to cover any exposed rubber with plastic wrap to keep it dry.

Temperature also plays a part in how and when a shipment of rubber can be moved. If the rubber gets too cold, it will crystalize and tear. Being left in the sun or in a warm place, however, can make rubber sticky, form soft spots, and deform. A metal truck in the summer sun could absolutely get hot enough to cause complications. If you’re worried about the temperature, you can usually request that the truck be insulated to prevent it from getting too hot.

Extra care should also be taken to ensure the rubber does not stick to anything, hence why talcum powder plays such an important role. When rubber sticks together or picks up debris, it can complicate the shipment, and even ruin it in a worst-case scenario.

Is natural rubber considered hazardous? Well, yes and no. The answer is a bit complicated.

When natural rubber burns, it burns incredibly hot (up to 1,200°C) and sputters, making the fire spread rapidly. It also produces thick black smoke that is composed of many harmful gases, making it difficult to get close to and extinguish. There are also other health concerns, such as severe reactions caused by latex allergies or from inhaling burning fumes.

However, according to the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), natural rubber is not classified as hazmat.

Even though rubber is not classified as hazmat, it is still dangerous. A safety data sheet should still be provided to inform workers and first responders on how to react if the shipment ignites.

If you have rubber to ship, you can count on R+L Global Logistics to get it delivered on-time and intact. With our 99.5% on-time delivery record and commitment to customer service, you can rest easy knowing your shipment is in capable hands.

Our experts have experience dealing with a wide variety of commodities and shipping requirements. If you have a time-sensitive shipment, we can also offer expedited shipping services and real-time freight visibility!

If you’re ready to get your freight moving, give us a call at (866) 353-7178, or fill out the online quote form to request a free freight quote!

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470