Maple syrup is hailed as a truly American commodity. Native Americans first discovered this delectable treat before the first settlers arrived, and to this day, North America is responsible for supplying the entire world with the vast majority of maple syrup. But how is maple syrup transported all across the rest of the United States?

How is maple syrup transported? Maple syrup is commonly transported by the truckload. It can be bottled before shipment in glass consumer bottles or large bulk containers, or it can be transported in a fluid tank truck. Because of the value of the commodity, it needs to be transported carefully.

Maple syrup is derived from a type of tree called a sugar maple (Acer Saccharum) tree, though there are several other types of trees that produce a sugary sap, like red maple, black maple, black walnut, and birch. However, sugar maple trees remain the tree of choice for producing the highest quality maple syrup.

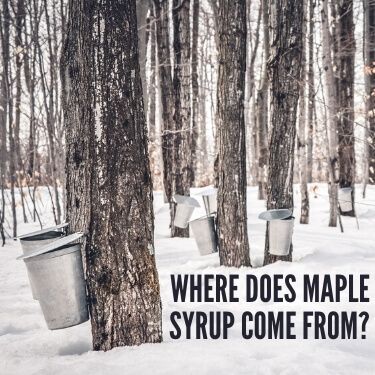

Most maple syrup originates from the woodlands of the North-Eastern U.S. and South-Eastern Canada, where sugar maple trees grow natively. The sap from these maple trees is called xylem, and it is harvested with taps drilled deep into the tree that drain the sap into collection buckets. However, the sap needs to be processed before it becomes the maple syrup that consumers would recognize.

Maple syrup is truly an icon of North-American agriculture since it is not produced significantly anywhere else in the world. Even though the weather conditions are perfect for sugar maples in some parts of Europe, there are only small-scale farms. Instead, roughly 90% of the entire world’s supply of maple syrup comes from a small forested region in North America around Quebec and the North-Eastern U.S. states.

Vermont is the number 1 supplier of maple syrup in the U.S. In fact, Vermont is so well known for its maple syrup, that the sweet treat has become a point of state pride. Just thinking about Vermont can bring images of maple trees and sweet maple candies to mind.

This reputation is well deserved. Vermont is responsible for producing 2.07 million gallons of maple syrup each year. That accounts for 48% of all U.S. maple syrup production! That is especially impressive, considering the season for harvesting maple syrup in Vermont is particularly short, and only runs from February to April.

New York State is the 2nd largest supplier of maple syrup in the U.S. Although it doesn’t have the same reputation as Vermont, it is still a large player in the maple syrup production industry. New York produces 17.8% of the maple syrup in the U.S., which equates to about 820,000 gallons.

New York’s climate is perfect for maple trees to flourish, meaning the harvest season is much longer than in Vermont. It runs from January to May, giving New York roughly two more months than Vermont to produce maple syrup.

Native Americans were believed to be the first people to reduce maple sap into syrup, and although it is still a sweetener beloved by many, maple syrup has had a bumpy history. For much of its early history, maple syrup could only be enjoyed by those that lived near maple trees. As transportation developed, however, maple syrup and other local commodities could spread out to more people across the U.S.

Before the Civil War, sugar began to fall out of favor with consumers because of its association with slave labor. That fact, in conjunction with the sugar shortage that happened during the war, resulted in consumers turning to maple syrup as a substitute. In the mid-1800s, maple syrup experienced a boom in popularity, but it was short-lived.

By the late 1800s, sugar began to dominate the market again. Because it could be cheaply produced, maple syrup just couldn’t compete and soon became a luxury only maple syrup producers, called sugarmakers, and wealthier people in the North could enjoy.

However, since the 1900s, maple syrup has gradually regained its popularity among common consumers, and now can be found in supermarkets across the nation.

Maple syrup is a versatile sweetener that can be applied to many different types of food. It is often used as a condiment or sweetener to baked goods, snacks, and beverages. It perfectly accompanies both sweet dishes and savory flavors.

Here are some examples of things you could put maple syrup in or on:

Most “pancake syrup” you see in plastic bottles in the store isn’t real maple syrup at all. It’s actually mostly corn syrup and artificial dyes and flavorings, made to imitate the look and taste of the real thing. It is cheap to produce, but it doesn’t really compare to genuine maple syrup.

So what exactly is “real” maple syrup? Well, sugar maple trees hold a lot of starch in their roots during the winter. When the weather begins to get warmer, that starch heats up and mixes with water to turn into sugar. That sugary sap, or xylem, then rises up throughout the tree, picking up its iconic flavor from the wood.

When the xylem is removed from the tree and boiled down, it becomes pure maple syrup. It is organic, with no added flavors, preservatives, or sweeteners. There are even laws in place to ensure that anything branded as real maple syrup follows a strict set of quality standards and guidelines.

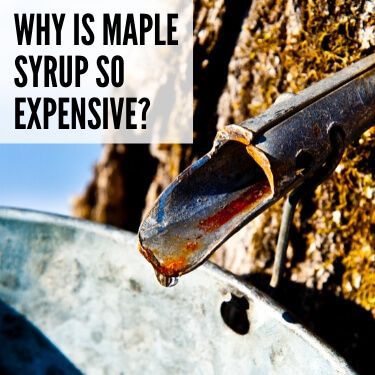

There are many factors that contribute to maple syrup’s considerable price tag. For one thing, maple syrup takes a long time to make, and it is a difficult and slow process to harvest the xylem from the trees. It requires patience, heavy lifting, and extreme temperatures to harvest, process, package, and sell the maple syrup, so naturally, it’s going to cost a little extra.

Sugar maple trees only produce good xylem in the spring, and usually only for a few months in the year. That automatically makes the commodity somewhat scarce, but that’s not the only thing. Each maple tree can only produce about 20 gallons of sap in a season. That might sound like a lot, but it actually takes about 40 or more gallons of sap to make just 1 gallon of syrup.

Then, you need to consider the fact that the trees that produce maple syrup are mature. A tree needs to have a diameter of 10-12 inches at chest height in order to even be used to make syrup. Until then, it simply takes up space as it grows. It could take up to 30 years before a new maple tree can begin to produce any profit!

Unfortunately, global warming is negatively impacting the maple syrup industry, causing less syrup to be produced each season. This means that syrup, although it is already expensive, will continue to get more valuable over time.

For a better understanding of how difficult the process is, you’ll need to take a closer look at the entire supply chain.

Want to move maple syrup south? Learn more about freight shipping from Vermont to Florida.

The process of making maple syrup begins in the wintertime, just before the sugaring season. The trees must be tapped in preparation for the spring, but first, the sugarmaker needs to determine how many taps the tree can sustain. If a tree has a diameter of about 10-12 inches, then it gets one tap. Trees 18-20 inches in diameter get two taps. Rarely, a tree larger than 25 inches in diameter will get three taps. Any trees that seem damaged or unhealthy will not get tapped since they are unlikely to produce syrup of acceptable quality.

Once that has been determined, the sugarmaker needs to install the taps. This is done by drilling a small hole about 1.5 to 2 inches into the tree at a slightly upward angle, to allow for the sap to flow out. If the wood shavings are light-colored, that indicates a healthy tree and the sugarmaker can move on to installing the taps.

A tap is installed by gently inserting into the drilled hole, and tapping it several times with a hammer. The sugarmaker has to find a sweet spot for how hard to hit the tap so that the tap cannot be removed by hand. If the tap is struck too hard, the tree may splinter, resulting in excessive damage to the tree and loss of valuable sap.

Once the tap is installed properly, the sweet sap can be collected either in buckets or by connecting tubes to the taps to drain into a collective container. The warmer days and freezing nights in early Spring encourage the xylem to move throughout the tree and out the tap into whatever collection method is utilized.

Once the xylem has been collected, it must be processed before it can be sold. Processing the syrup takes quite a while, but once that is done, sugarmakers have several options for how they want to sell their product. Most small-scale operations sell small bottles to consumers, or create treats and other products to sell like candies and cookies. Large-scale companies are far more likely to sell their product in bulk to restaurants, manufacturers, and grocery stores.

Fresh sap does not store well, and must be processed as soon as possible or else it will spoil. This is especially true for warmer days since temperatures above freezing encourage the growth of bacteria that can ruin the entire batch. Losing a batch of sap can be a huge waste of profit, so sugarmakers need to be careful about leaving their sap unprocessed for more than a day or two.

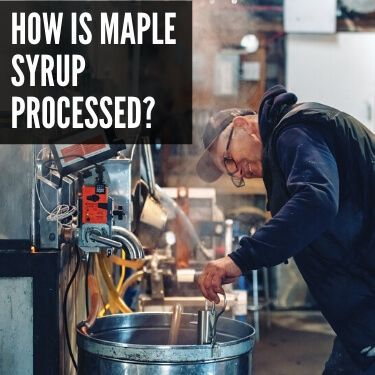

Before the processing can begin, the sap must be filtered to remove any debris, like wood shavings, dirt, and insects. Then, the sap is pumped into an evaporator, which is a large machine that continuously boils the sap to reduce the sap into a sugary syrup. Before processing, the sugar content of the sap is only about 1% or 2%, and it must get to at least 66% sugar content before it is considered maple syrup.

Sugarmakers use what’s known as the Rule of 86 to help them calculate the costs of processing a single batch of syrup. This is a helpful calculation that uses the sugar content of a batch (measured with a refractometer) to determine how many gallons of sap will produce 1 gallon of syrup.

The rule is based on the fact that sap with 1% sugar content would require 86 gallons to make 1 gallon of syrup. So, sap with a 2% sugar content would require 43 gallons of sap to make 1 gallon of syrup. To use this, the number 86 has to be divided by the percentage of sugar content in a batch. As you can see, the percentage of sugar in the xylem before processing has a huge impact on the rest of the process.

The boiling point of syrup is slightly higher than water, which is an important thing to keep in mind when processing this delicate commodity. Maple syrup boils at between 219-220 degrees Fahrenheit. If the sap is processed at the wrong temperature, it could have a negative impact on the quality and grading of the final syrup.

It is also important to make sure the syrup is boiled for the right amount of time. If a batch is boiled for too long, it will begin to crystallize. However, if the batch isn’t boiled long enough, it will spoil before it could even reach consumers. The appropriate sugar content is about 66% or roughly 11 pounds per gallon.

After the syrup has been boiled, it is filtered hot and either bottled or moved to a large holding tank to be shipped.

The quality of real maple syrup is a huge deal and is taken very seriously by sugarmakers, restaurants, consumers, and even the law. In order to receive a seal of quality, the maple syrup must be grade A. So, how do you determine the grade of a batch of maple syrup?

Thankfully, the grading scale is the same in both the U.S. and Canada, making it a consistent standard for quality maple syrup around the world. The Canadian Food Inspection Agency (CFIA) and the United States Department of Agriculture (USDA) agreed to harmonize the grading scale in 2015.

Previously, maple syrup was graded based on the color and intensity of flavor, but now, the grades better reflect the actual quality of the product. While there used to be grades A, B, and C, with A being the most expensive and C being the least, now syrups are graded as either A, Processing, or Substandard.

Grade A syrups must have no more than 68.9% sugar content, and they should have no cloudiness or odd scents or flavors. They should be uniform, smooth, clean, and have the appropriate maple flavor and sweetness for the color class.

Grade A syrups can be:

The lighter the syrup, the sweeter and more valuable it is. The color of the syrup depends on when it was harvested. The first few batches of the season are often light-colored, while the end of the season tends to produce darker syrups. Other factors can also influence the color, like how long the syrup sits out before being processed, and how long it takes to evaporate the water during processing.

Processing grade syrups are syrups that don’t quite meet the quality guidelines to be considered an A grade. Syrups that fall under this category might have off-flavors or too strong of a maple taste. Like A class, they cannot have a sugar content higher than 68.9%.

Processing grade syrups cannot be sold to consumers, however, they are still perfect for manufacturing into other products like cookies and sweets. Because of this, processing grade syrups can only be sold in containers that are 5 gallons or larger.

Substandard grade syrups are syrups that do not meet the requirements for being graded as A or Processing. A substandard syrup can not be sold, either to customers or manufacturers. In most cases, sugarmakers that produce substandard syrup must consider it a loss and discard the batch.

If you want to get your maple syrup to consumers across the U.S., then you’re going to need to have a plan for transporting it. But before you can even start worrying about transportation, you need to make sure you pack your syrup safely so that it doesn’t get damaged along the way.

When bottling maple syrup for consumers, there are two important things to keep in mind: the bottles should be glass, and the syrup should be hot when it is being bottled.

The reason it is important to use glass, especially for lighter and more delicate syrup, is because it is the best material for preserving the flavor of the maple syrup. Plastic can sometimes add off-flavors to the syrup, damaging the product’s quality. If the syrup is already dark and already has an intense maple flavor, using plastic would be acceptable, though not recommended.

The reason syrup should be bottled hot, at a temperature of about 180-200 degrees Fahrenheit, is to prevent mold and bacteria growth in the sealed containers. If the syrup is not hot enough when it is bottled, then a film of mold may grow on the surface of the syrup, rendering it inedible. Hot packing the syrup is another reason why it is a better idea to use glass than plastic bottles since some plastic can melt at 200 degrees.

Once the syrup is bottled, you must ensure that there is adequate space between the bottles to allow the syrup to cool down. Being too hot for too long could darken the syrup and decrease its overall quality.

In order to sell your bottles of syrup to consumers, you will need to ensure that they are properly labeled to meet the standards of the Food and Drug Administration (FDA). To be compliant, the label should include:

If the label includes a statement about health claims, such as “no sugar added,” then it must also include a nutrition facts label.

Additionally, sugarmakers may want to include the grade of the syrup on the label for marketing purposes, but this is completely voluntary. If the information is included, however, it must be accurate.

In order to ship your bottles of maple syrup anywhere in the country, you’re going to need to make sure you package them carefully. Glass is very fragile, and losing even a single bottle of this valuable commodity would be a serious loss.

The first step is to find a sturdy box to pack the bottles into. It should be reinforced cardboard or wood, so it is durable enough to protect the syrup from damage and allow for other boxes to be stacked on top of it. By being able to stack the boxes, you will be able to palletize the shipment, making it far easier to transport by truck.

Most carriers are not going to palletize your shipment for you, so you need to arrange to have it palletized before it is picked up for shipment. However, a third-party logistics company may include palletization as part of its warehouse services.

When packing the box, ensure that there is enough space between the bottles to put some packing materials, so the bottles do not bump into each other and break. You could use foam, cardboard, or any type of packing material, as long as you are confident that it will protect the glass from breaking.

Shipping your maple syrup in small glass bottles is great if you are selling your product to consumers, but if you need to ship a large quantity of syrup to a big manufacturer, then bottling the syrup in little 16oz bottles would be silly. In fact, more than half of all maple syrup from New York is shipped in bulk, so chances are, this is a situation you’re likely to encounter.

If you need to need to ship your syrup in bulk, there are a couple of different ways you can go about doing that.

When a large quantity of maple syrup needs to be delivered to a food service location, like a restaurant, it needs to be in a reasonably sized container for their purposes. If a restaurant serves hundreds of plates of pancakes a day, they’re going to need more than a few little bottles. The best way to ship to restaurants is in bigger containers, so it saves space and reduces waste from empty containers.

Some options for bulk containers are:

The option you end up using is going to depend on the resources you have available and the needs of your customers. One option isn’t necessarily better than the others, but one might suit your business better than another.

If you’re transporting processing grade syrup to a manufacturer, then you’re going to need to move a much greater volume of syrup at a time. The best way to move several hundred gallons of syrup in one trip is with a large tank truck. However, there are a few things to keep in mind when shipping maple syrup by tank truck.

Tank trucks have a maximum weight limit of 80,000 lbs, but that depends on the number and spacing of the axles on the truck. A two-axle truck could only move up to 36,000 lbs, while a one-axle truck could only move 22,400 lbs. Consider how much syrup you have to move before deciding on an option since you could save some money if you go with a smaller truck.

One thing to note about maple syrup is that because of its sugar content, it is much heavier than most other fluids. A tank truck might only reach the weight limit filled all the way to the top with something like gasoline, but a tank filled with maple syrup might need to have some space left in the tank to ensure it doesn’t get above the legal weight limit.

Any commercial vehicle moving across state lines must be in compliance with the Federal Motor Carrier Safety Administration (FMCSA) regulations. This government organization ensures that all commercially operational vehicles are operated safely, to reduce accidents on the road. There are licensing, substance testing, pre-screening, and certification requirements that are in place to ensure that the driver and the vehicle are both fit for the job.

In addition to those regulations, it is also important that the vehicles are carefully maintained, and inspected both before and after each trip. The FMCSA also maintains the right to perform roadside inspections and safety audits, to ensure that all safety regulations are being abided.

When shipping anything into a state other than the one in which you live, you are probably going to deal with the complicated mess that is state sales tax. It is the seller’s responsibility to be aware of the different tax rates in states they’re shipping to, but it can be helpful to outsource to a bookkeeper or accounting service to ensure you don’t make mistakes and get prohibited from selling to that state in the future.

Because maple syrup is often compared to its counterpart, honey, most people assume that maple syrup doesn’t spoil. This is not the case. Even though maple syrup has a considerable shelf life, it will go bad if it is not stored properly. Spoiled maple syrup could adopt an off-putting smell or bad taste, or it may even grow a film of mold over the surface of the syrup. Take maple syrup storage seriously, especially if you intend to sell your product to consumers.

As a general rule, an unopened bottle of real maple syrup will last about a year in room-temperature storage. Once the seal on the bottle has been broken, it must be kept in cold storage. An opened bottle of maple syrup will last about one year in the refrigerator. If a bottle of maple syrup is frozen, it will last indefinitely.

Those estimates are generally a good basis for determining if maple syrup is still good, but obviously, if you test a bottle and it doesn’t look or taste quite right, it should be thrown away.

Now that you know how maple syrup is transported, you might be preparing to make a shipment of maple syrup yourself. Well, you can rely on R+L Global Logistics to pair you with a trusted and reliable carrier to move your freight safely. We offer a range of services that makes the process of shipping maple syrup easier, like expedited shipping, white-glove services, and temperature-controlled shipping. Regardless of whether you’re shipping pallets or a large tank full of maple syrup, we can help you every step of the way!

Contact us today for your freight shipping quote!

R+L Global Logistics

315 NE 14th St., Ocala, FL 34470